The electrification of vehicles offers many advantages compared to a powertrain with an internal combustion engine. New developments in the field of electrical machines and semiconductor technology facilitate new electrical drive concepts. These allow for the efficient and highly dynamic use of electrical machines, thus enabling continuous power transmission over the entire speed range and also short-term overloads. A single electric machine with a fixed mechanical connection to the wheels is often used as the main drive in such a drive train. The high torque requirement on the wheels is achieved by a high transmission ratio via a gearbox and a differential. Dividing the main drive into several electrical machines results in a large number of drive topologies result.

The wheel hub and near-wheel drives have a major advantage in terms of flexibility in the body structure, as the wheels no longer have to be mechanically connected to each other. Due to the mechanical decoupling of the wheels, a wheel-ground slip control (torque vectoring) can be implemented. By using high-torque electrical machines (high-torque machines), additional gear stages can be saved.

Torque density in an electric machine can be increased either by raising the magnetic field strength in the air gap or by changing it via the rotor position (increasing the number of poles). Both possibilities are limited by the soft magnetic material used and by the air gap length between stator and rotor. The surge in the number of poles in conventional electrical machines is limited by the conflict of objectives between maximizing the copper and iron cross-sectional area.

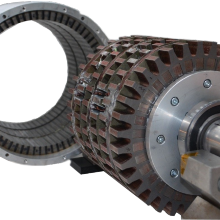

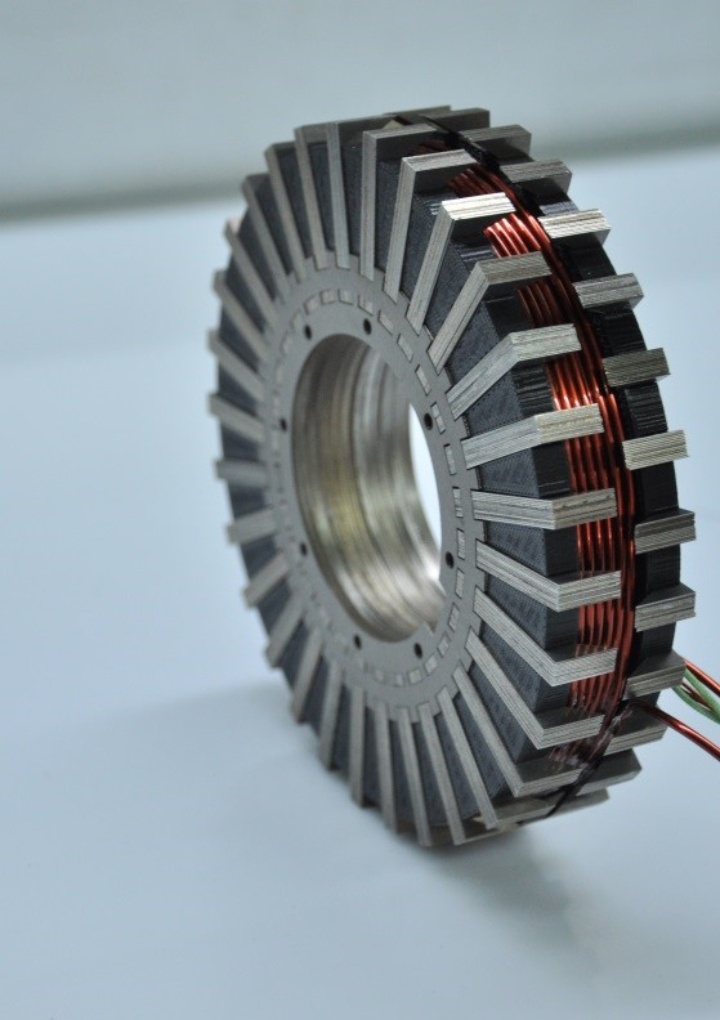

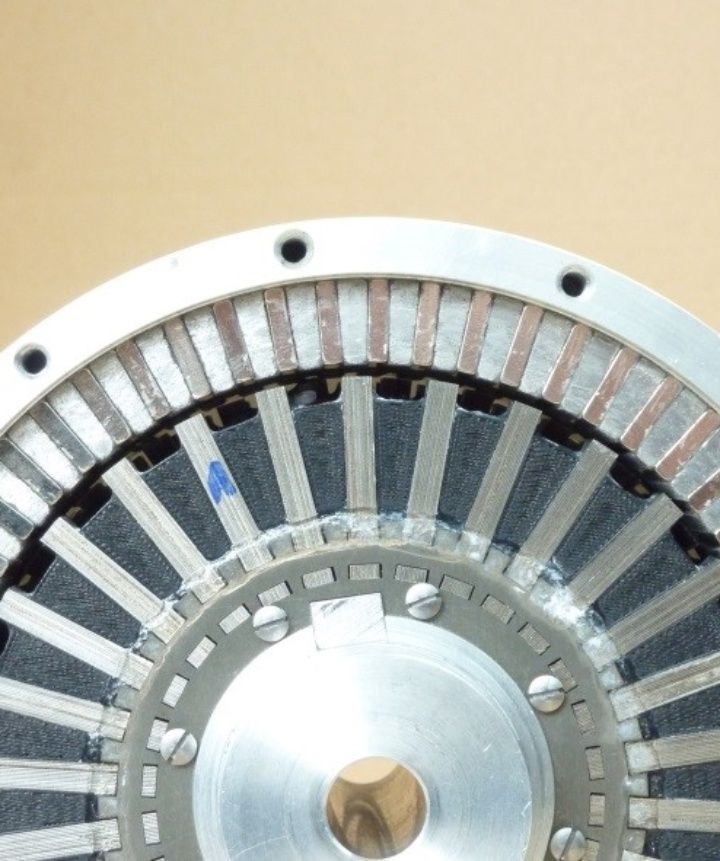

The transversal flux machine (TFM) solves this conflict of objectives by decoupling the maximization of the copper and iron cross-sectional area. This allows the number of poles to be further increased until the soft magnetic material and the air gap length reach their maximum capacity. However, this results in an additional magnetic flux component that runs transversely with respect to the direction of movement from which the name of the TFM is derived. The flux components in the radial direction and the direction of rotation result in three-dimensional magnetic flux guidance in the TFM. The significant rise in the number of poles in the TFM leads on the one hand to a linear increase in the stator frequency, which, in turn, causes an increase in hysteresis and eddy current losses. On the other hand, the number of poles heightens the inductance, which in turn increases the reactive power requirement or reduces the power factor. This indicates that a TFM is suitable for use in applications with high torque and low speed requirements.

In addition to the possibility of increasing the number of poles, the TFM also leads to additional manufacturing advantages in the manufacture of the winding. However, this also leads to considerable challenges in the implementation of three-dimensional magnetic flux guidance. The alternating magnetic fields induce voltages in the soft magnetic material that cause eddy currents orthogonal to the field change. In order to reduce these eddy currents, the three-dimensional magnetic flux guidance has to be implemented using powder composite material (Soft Magnetic Composite) or several bundles of mutually insulated sheet metal.

Further, the individual strands of the TFM are mechanically and partially magnetically decoupled from one another compared to conventional electrical machines. In order to generate a constant total torque, the individual strands need to be offset relative to each other in the direction of rotation. Due to the high number of poles, even the smallest deviations lead to noise and a large detent torque. Furthermore, the topology of a TFM in the soft magnetic part promotes partial saturation effects. The two reasons mentioned above lead to significant control engineering challenges in the operation of the TFM.